Why Use Joints? Because Structures Want to Move!

Expansion joints are separations between structures, simply gaps, to allow them to move and reduce stresses that may occur.

Often, these gaps are filled with an Expansion Joint System to fill in the void to ensure walkability, a complete building enclosure, waterproofing, and general serviceability of the structure.

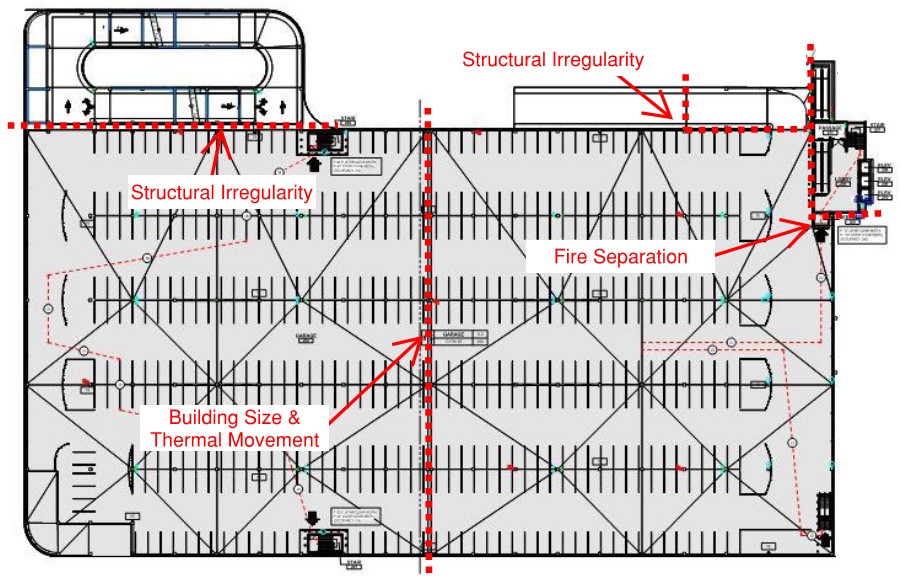

There are many reasons expansion joints are required such as:

- Structure Size / Length

- Structure Shape or Irregularities

- Isolation of Dissimilar Building Classifications

- Fire Separation

- Thermal Movement

Joint Locations

What you need to know!

There are many different types of systems for accommodating movement gaps in structures. Expansion joints occur through all parts of a structure to provide complete separation – through floors, walls, ceilings, and roofs (interior & exterior).

- Floor-to-floor

- Floor-to-wall

- Wall-to-wall

- Ceiling-to-ceiling

- Ceiling-to-wall

- Roof-to-roof

- Roof-to-wall

- Joints are generally not required at on-grade floors

- Systems may or may not be waterproof

The size of the gap should be as small as possible to fit the design movement, and the size of the expansion joint system needs to accommodate the full range of expected movements. For example, a gap may grow and shrink seasonally due to temperature changes; the joint system needs to stretch to fill the widest opening but it also must not buckle when the system closes to its smallest size. Expansion joint systems also may need cover or protect fire-stopping systems.

So, Who will help you?

How will you decide on the type and size of joint that is right for your structure? Here is the breakdown of key roles and responsibilities of your team.

Engineer

- Provide the expected movement

- Be clear in expectations

Contractor

- Engage supplier/manufacturer

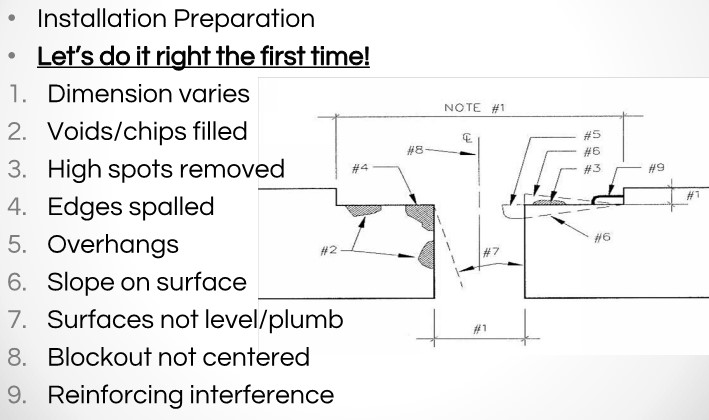

- Prepare joint’s blockout

- Communicate when installation will happen

Supplier

- Inspect the conditions

- Review engineer’s data

- Size joint based on data and install time

There are numerous steps to coordinate in this process so it’s important to understand clearly who will perform which tasks in this process.

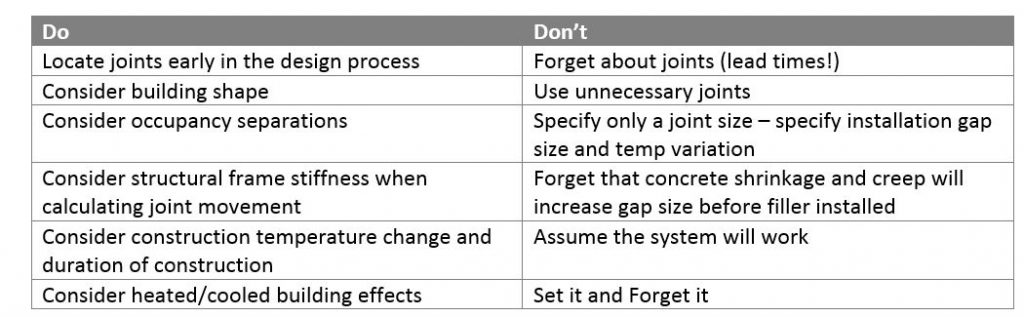

The entire project team needs to work together to ensure success. To start, the lead Architect or Engineer determines the style of joint system and the Structural Engineer determines locations of gaps. The Structural Engineer then provides the anticipated movements and minimum gap sizes to the construction team. Often, a full range of movements for an installation temperature need to be provided on the Construction Documents to clearly express the requirements of the system’s movements.

The Contractor then reviews this information and engages the joint system manufacturer or vendor to recommend the size of system appropriate for the expected movements. It’s often helpful to have the Engineer verify the selected system for conformance with movement needs.

Once a system is selected, the Contractor needs to provide an appropriate substrate for the system’s installation, but also have the system manufacturer confirm that the location is adequately prepared for installation. If everything is ready, a qualified Contractor will then install the system and it will perform well for many years.

After assembling your team where should you start?

The Dos and the Don’ts…

After taking all of these items into consideration you will be well on your way to successfully incorporating expansion joints into your design!

About the Author: Carl Schneeman, PE is the Director of Operations in Walker’s Minneapolis office. He has an extensive background in structural design, testing and construction. With Walker, he has led many successful new design and restoration projects ranging in size from under $100,000 to over 40 million dollars in construction cost.